Enterprise AI

Custom AI

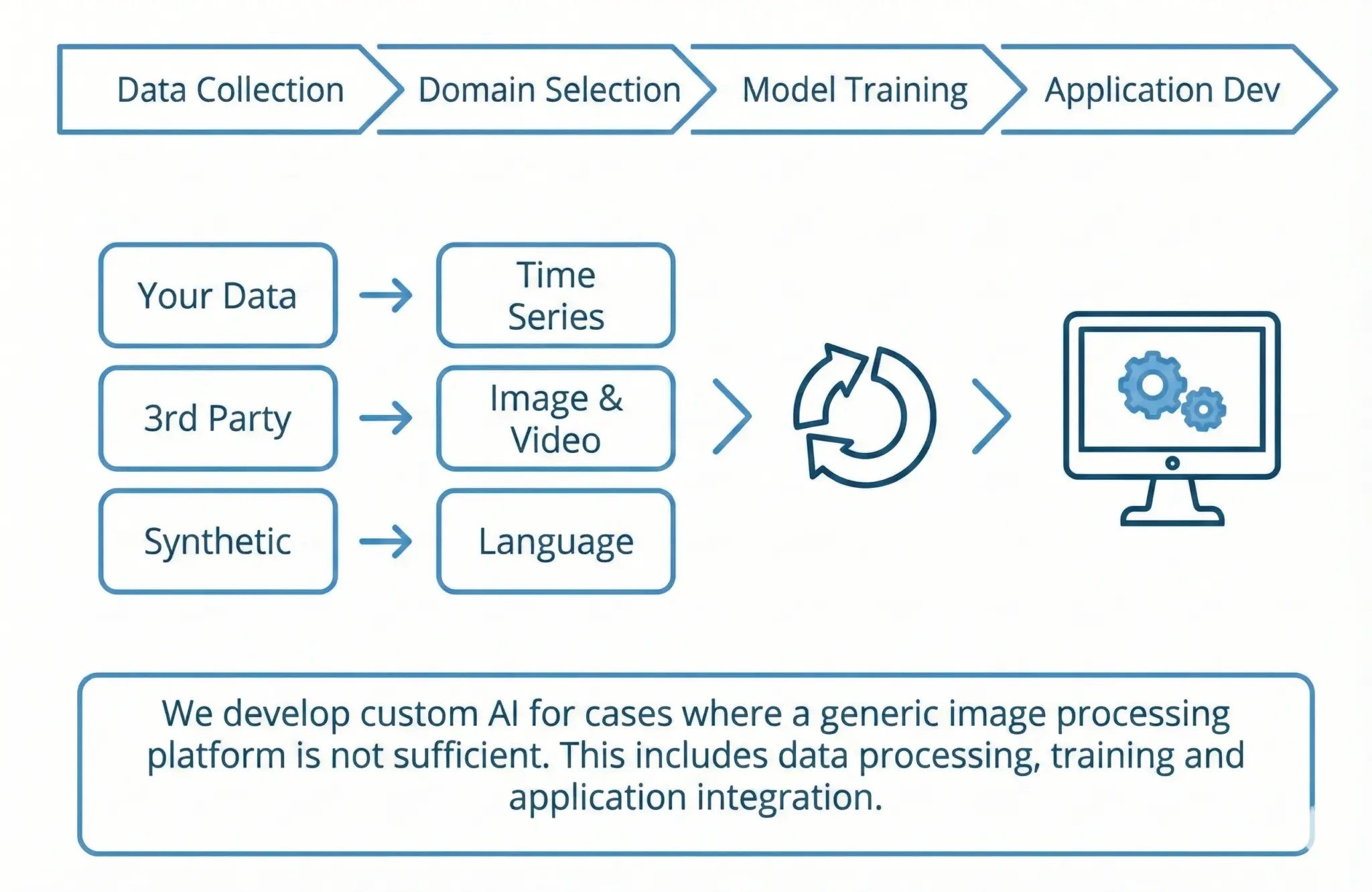

Custom AI Solutions: Going Beyond Generic Platforms.

Data Collection:

Leveraging proprietary, third-party, and synthetic data for robust datasets.

Domain Selection:

Specialized solutions for Time Series, Image & Video, and Language processing.

Model Training:

Iterative optimization loops to ensure high precision for your specific use case.

Application Dev:

Seamless integration of models into fully functional applications and workflows.

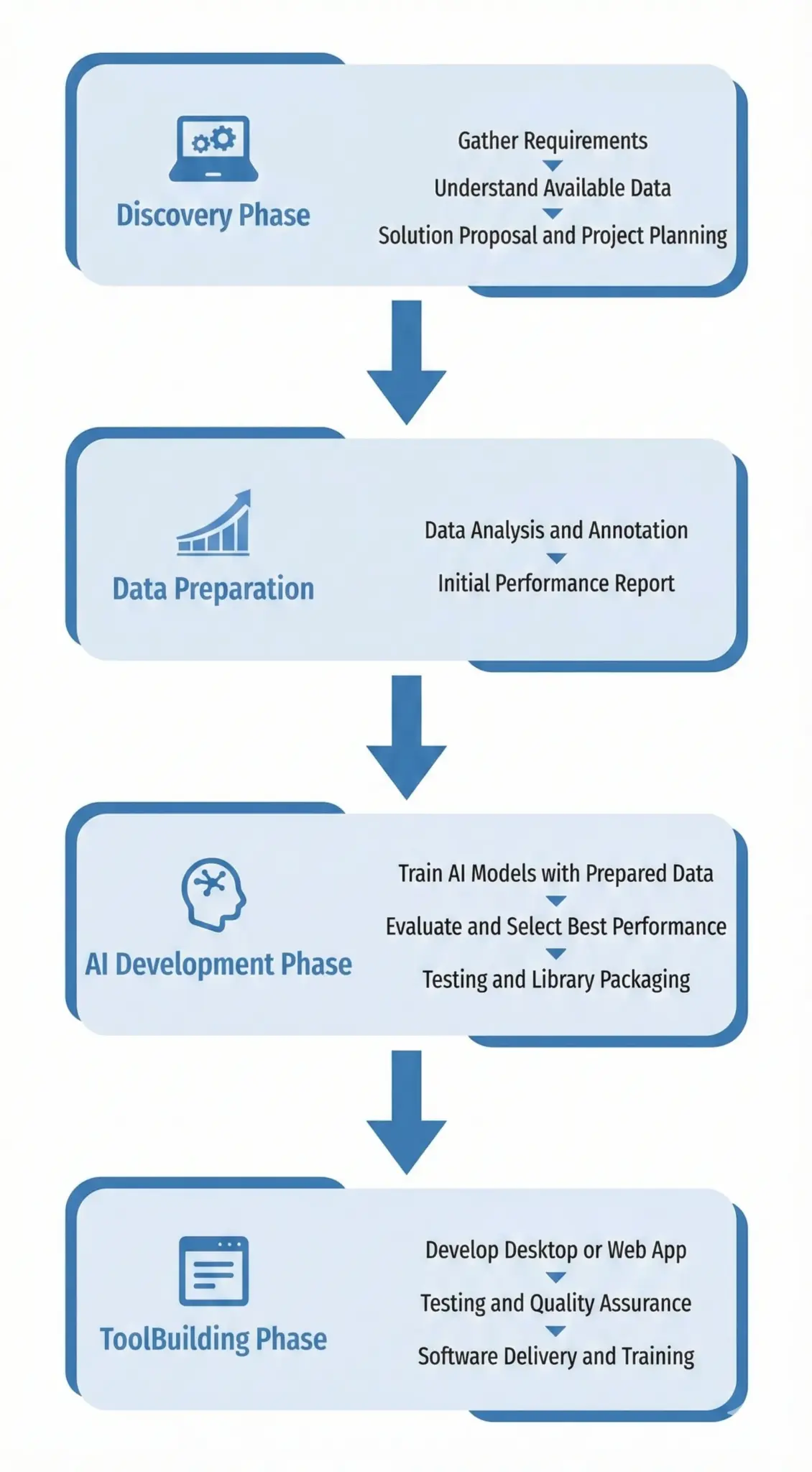

Service flow

Our process takes you from idea to deployment with a reliable, structured workflow.

We start by understanding your goals and data, prepare and validate the dataset, then build and refine the AI model. Finally, we package everything into a desktop or web application, complete with testing, delivery, and training.

Work with ArtFreak

Conversation Intelligence for Sales Teams

LLM-driven analysis of real-world sales interactions

Our solution integrates advanced speech-to-text and large-language-model analytics to process recorded sales discussions. It extracts key phrases, maps word networks, compares conversation patterns across groups, and surfaces improvement points. This enables organizations to coach their teams with objective, scalable insights based on real customer interactions.

Automated Soil Classification for Tunnel Boring Operations

Deep learning that helps crews spot trouble before it becomes expensive

Work with Enzan

We developed a vision based analysis system that monitors the soil coming out of a tunnel boring machine and turns a simple video feed into a real time quality indicator. The model was trained on carefully labeled data and learned to recognize subtle shifts in material that often signal issues inside the cutter head. This gives operators an early warning window, letting them adjust settings or perform checks before a small irregularity becomes a full stoppage.

To keep hardware costs under control, we also optimized the model so it can run smoothly on non GPU devices. The result is a practical tool that reduces downtime, cuts operating costs, and gives TBM crews clearer insight into what is happening underground.